en

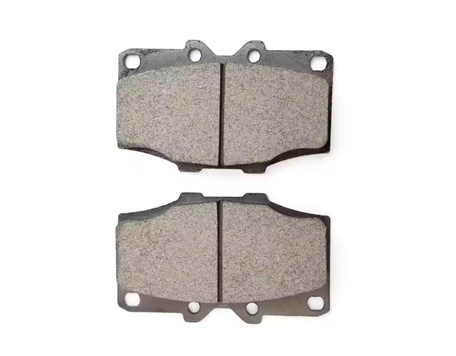

The brake shoes are curved metal components lined with friction material, used in drum brake systems to slow or stop a vehicle. When the brake pedal is pressed, hydraulic pressure forces the shoes to expand outward against the inner surface of the rotating brake drum, creating friction and deceleration.

Each brake shoe consists of a steel backing plate bonded with a high-friction lining, often made of heat-resistant materials like ceramic, metallic, or organic compounds. Unlike disc brake pads, brake shoes are curved to match the drum’s interior shape. They operate via a wheel cylinder, return springs, and an adjuster mechanism, ensuring consistent contact and wear compensation.

Commonly found in rear-wheel brakes of older cars, trucks, and heavy-duty vehicles, brake shoes are durable and cost-effective. However, they are prone to heat buildup, fading under heavy use, and slower heat dissipation compared to disc brakes.

Regular inspection is crucial to check for lining wear, oil contamination, or cracked components. Worn-out shoes reduce braking efficiency and may damage the drum. Though less common in modern passenger cars, they remain vital in commercial and vintage vehicles due to their simplicity and reliability.

Email us

Call us

Address

NINGBO. ZHEJIANG. CHINA