en

Stamped Steel Rocker Arms

The Stamped Steel Rocker Arm is probably the most common style of production Rocker Arm. They are the easiest and cheapest to manufacture because they are stamped from one piece of metal.

They use a trunnion pivot that holds the rocker in position with a nut that has a rounded bottom. This is a very simple way of holding the rocker in place while allowing it to pivot up and down.

Roller Tipped Rocker Arms

The Roller Tipped Rocker Arm is just as it sounds. They are similar to the Stamped Steel Rocker and add a roller on the tip of the valve end of the rocker arm. This allows the for less friction, for somewhat more power, and reduced wear on the valve tip.

The Roller Tipped Rocker Arm still uses the trunnion pivot nut and stud for simplicity. They can also be cast or machined steel or aluminum.

Full Roller Rocker Arms

The Full Roller Rocker Arm is not a stamped steel rocker. They are either machined steel or aluminum. They replace the trunion pivot with bearings. They still use the stud from the trunnion pivot but they don't use the nut. They have a very short shaft with bearings on each end (inside the rocker) and the shaft is bolted securely in place and the bearings allow the rocker to pivot.

Shaft Rocker Arms

The Shaft Rocker Arms build off of the Full Roller Rocker Arms. They have a shaft that goes through the rocker arms. Sometimes the shaft only goes through 2 rocker arms and sometimes the shaft will go through all of the rocker arms depending on how the head was manufactured. The reason for using a shaft is for rigidity. Putting a shaft through the rocker arms is much more rigid than just using a stud from the head. The more rigid the valve train, the less the valve train deflection and the less chance for uncontrolled valve train motion at higher RPM

Center Pivot Rocker Arms

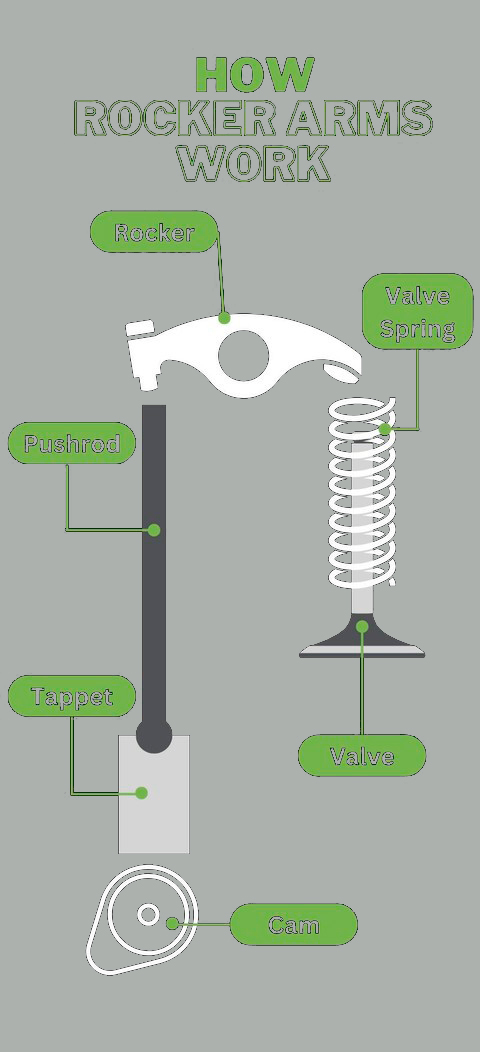

The Center Pivot Rocker Arm looks like a traditional rocker arm but there is a big difference. Instead of the pushrod pushing up on the lifter, the Cam Shaft is moved into the head and the Cam Shaft pushes directly up on the lifter to force the valve down. In this case the pivot point is in the center of the rocker arm and the Cam Shaft is on one end of the rocker arm instead of the pushrod

End Pivot (Finger Follower) Rocker Arms

The End Pivot or Finger Follower puts the pivot point at the end of the Rocker Arm. In order for the Cam Shaft to push down on the Rocker Arm is must be located in the middle of the rocker arm.

Email us

Call us

Address

NINGBO. ZHEJIANG. CHINA